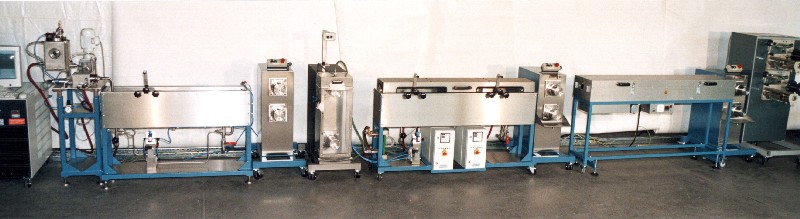

Laboratory and Pilot Wet Spintesters

Several polymers like Hydrocellulose, PAN, Acetate, and Polyurethane, but also e.g. Polyamide monofilaments, are wet spun. This results in different process requirements

regarding solvent, concentration of the solution and materials of parts like vessels and spinnerets.

Based on a modular system Fourné is able to offer laboratory and pilot plants that allow working with most spin dopes. This permits research and development of:

|

spinnability of new fiber polymers, spun from a solution |

|

production of small amounts of filament yarns or fibers as well as bulk samples for production tests |

|

testing of new solvents |

|

testing of changes in solids content of the spinning solution |

|

new fiber polymers for solution spinning processes |

|

optimization of the spinning process for transfer into the production |

The high flexibility is achieved by several design advantages, e.g.:

|

selection of vessel size according to the available amount of solution |

|

single dope vessel for batch operation or multiple vessels for continuous operation |

|

optimum solution preparation and homogenization with advanced stirrer design |

|

homogenous temperature of the spin dope within a wide temperature range |

|

exchangeable precision spin pumps for a wider throughput range |

|

exchangeable spinneret holders for horizontal spinning in the coagulation bath, vertical spinning in the coagulation bath or air gap spinning |

|

height adjustable coagulation bath |

|

individual temperature adjustment of the washing and stretching baths, hot air channels and drum dryers |

|

flexible configuration of baths and dryers, optionally moveable on wheels |

|

advanced process control and automation system, operated from a PC close to the spinning unit, optionally with master speed control |

|

optionally explosion proof execution of susceptible components |